TECHNOLOGY OVERVIEW

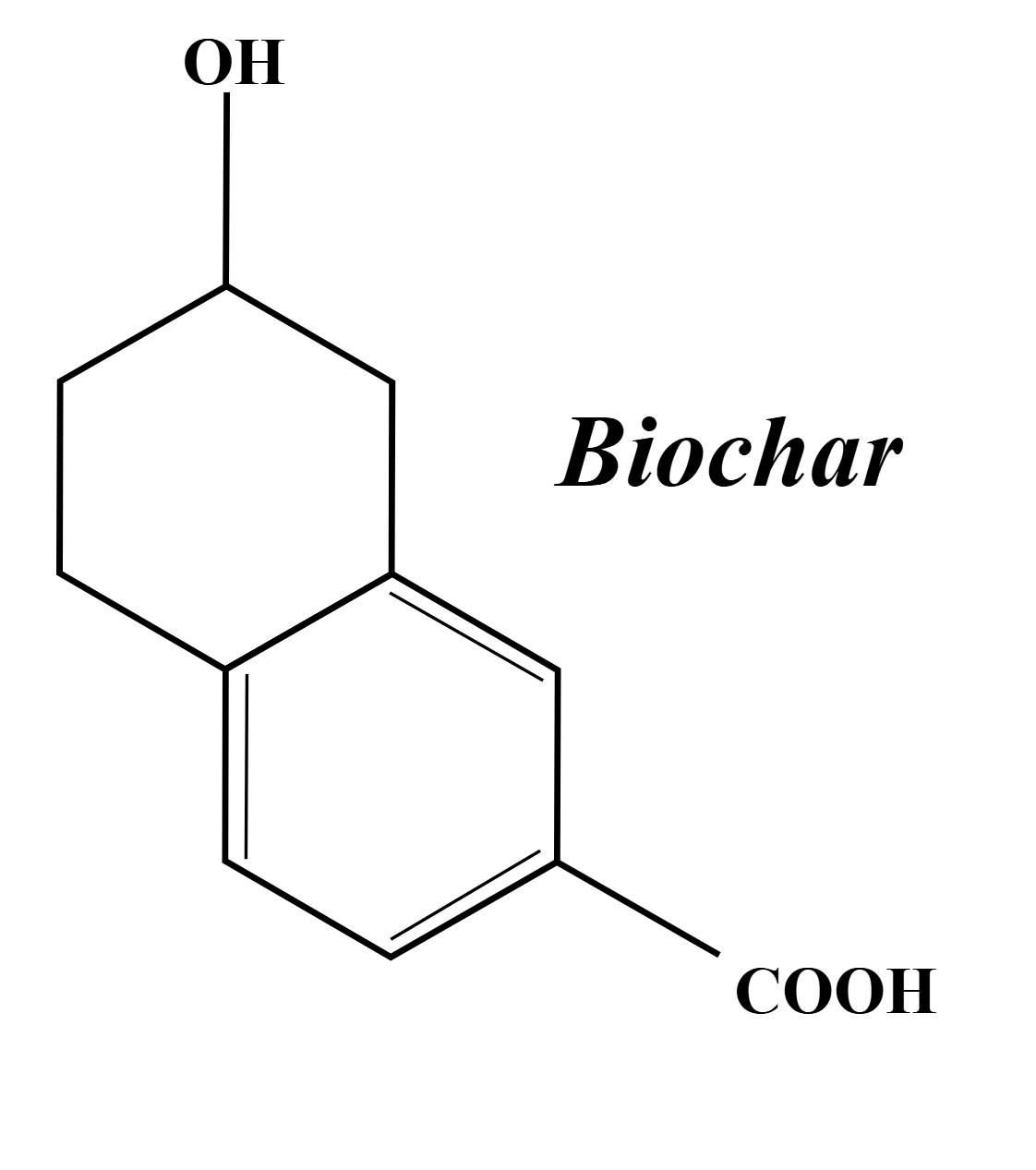

The team led by Professor Martel and Dr. Al Akoumy at Université de Montréal has demonstrated a novel method to treat biochar with sulfur enabling the synthesis of a stable and highly durable biochar material.

The resulting biochar exhibits considerably improved mechanical strength and chemical stability reaching in optimized parameters a compressive strength of 382 MPa and a Young’s modulus up to 165 GPa, while retaining a low density of 1.3 g/cm³, highlighting its potential for lightweight structural applications. Aiming for an industrial oriented process, the manufacturing process does not require high temperature, potentially allowing the scale up with production technologies such as extrusion. The novel biochar-sulfur material processing may allow the final part to be shaped into fibers, pellets, sheets or beams using compression molding. The versatile material unlocks new use for biochar as lightweight strong carbon-storing reinforcement for structural and mechanical applications.

The team is engaged in the scale up of the production to test the biochar-sulfur materials in various applications. We are looking for industrial partners to identify the key features to tackle in order to develop and tailor this novel material at industrial scale.

Mechanical properties comparison

|

Materials

|

Compressive strength (MPa) |

Young’s modulus (GPa) |

Density (g/cm3) |

Tensile strength (MPa) |

|

Our biochar

|

20 to 383 |

6 to 165 |

1.3 to 1.4 |

Not tested yet

|

|

Steel

|

170-180 |

190-210 |

7-8 |

350-420

|

|

Concrete

|

15-20 |

20-40 |

2.-1 |

0.9

|

| E-Glass fiber |

4000-5000 |

43-50 |

2.5 |

1900 – 2000

|

| Carbon fiber |

700 -1000 |

200 – 600 |

1.8 |

1000-4000

|

BUSINESS OPPORTUNITY

- Co-development partnerships for technology maturation

- Admissible to research/industry government grants for technological development

COMPETITIVE ADVANTAGES

- High strength and ultralight material

- Durable and chemically stable

- Scalable manufacturing

MARKET APPLICATIONS

- Composite material reinforcement

- Molded parts in advanced manufacturing

- Transport and storage of biochar

IP PROTECTION

- US Provisional Patent Application